The intelligent information Request and Delivery Standard (iiRDS) defines uniform metadata for all information products. This simplifies the exchange of information, for example, between a manufacturer and its suppliers. But iiRDS can also improve information processes within the company, as it does at Siemens Energy.

An Interview with Michael Straeter and Tobias Köffer from Siemens Energy provides answers.

How did you come across iiRDS?

Michael Straeter: We first became aware of the topic through tekom publications and events. We have been discussing the topic internally since 2018 and have been talking to service providers and suppliers. We then set up our first pilot project in 2019. The question was if we could display our central information products in iiRDS. And that worked.

Tobias Köffer: Independently of the changes to our own information products, we also looked into the possibilities of (semi-)automatically assigning metadata. The aim was to efficiently process content created outside the CCMS [Component Content Management System] to make it usable in a targeted manner. It very quickly became clear that this could not continue in the long term without a standard, and iiRDS was the obvious choice.

Why did you choose iiRDS?

Michael Straeter: In a large company like Siemens, later Siemens Energy, there are many competing requirements, developments, and standards side by side. When we introduced our CCMS, we decided in favor of PI-Mod and against DITA. But we soon realized that without a guiding standard, we were making our taxonomy immeasurable and increasingly incomprehensible – precisely because in the power plant sector we are dealing with huge product ranges, a vast amount of required information, and a great many “standards” in the departments involved. When we started to look at expanding our editorial portfolio – in case the era of fossil fuel power plants does come to an end – it was clear to us that it would not work without a radical pruning of the taxonomies and a standardization and minimization (keyword DIN EN IEC/IEEE 82079-1). On the information side, iiRDS seemed to us to be a promising approach. On the product side, after some analysis and trial and error, we also found a more generic approach. However, both together also had an impact on our information products and editorial processes.

Tobias Köffer: We are trying to create a tool-independent and standardized way for information recipients to access and work with our content. We are also making our work a little easier for the future and laying the foundations for increasingly digital and granular use, even in our fairly traditional environment of power plant construction.

Which products do you use iiRDS for?

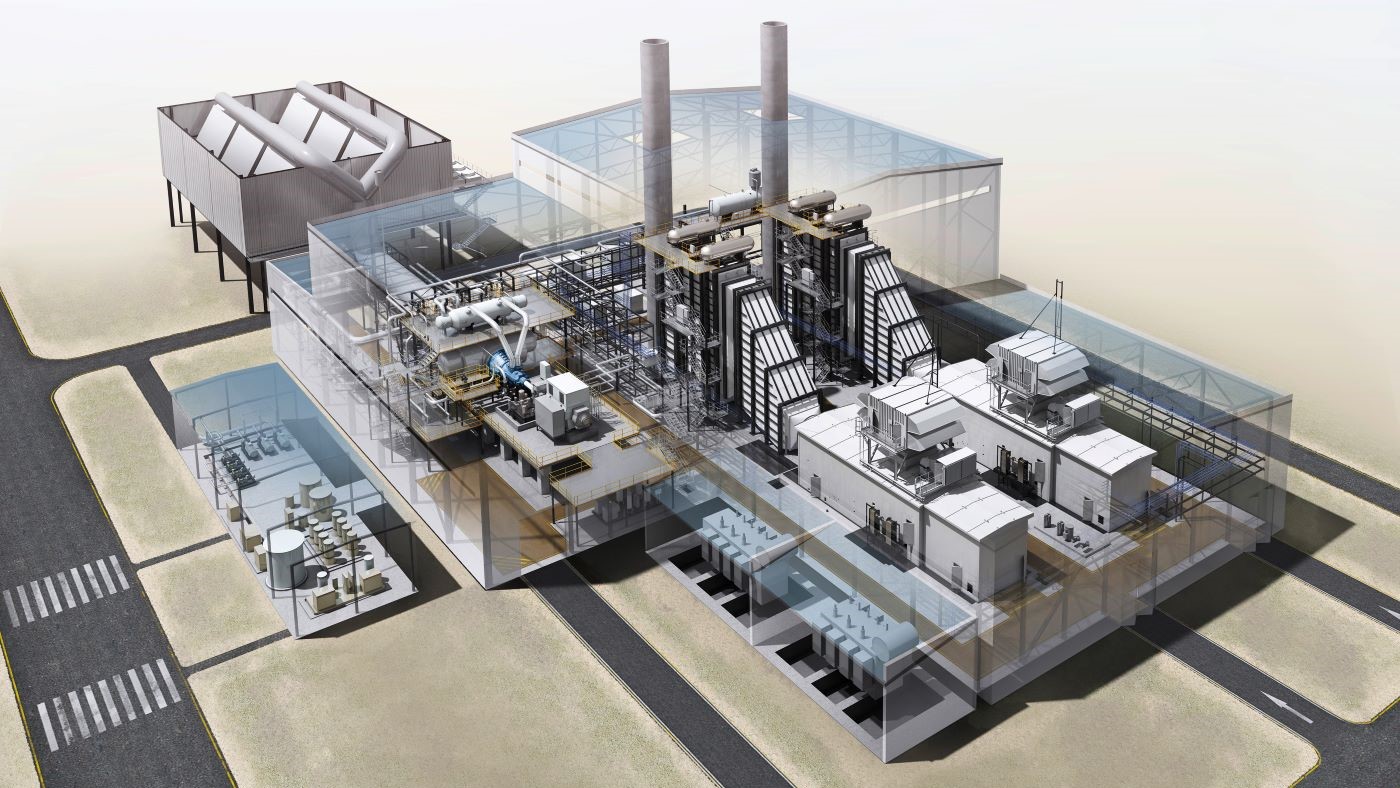

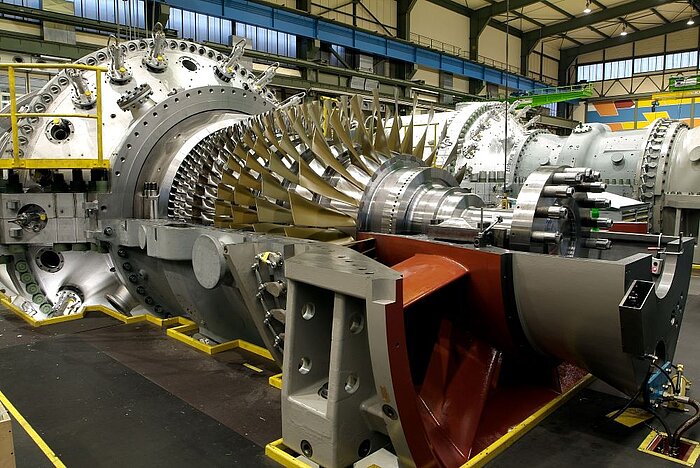

Michael Straeter: At the moment, mainly components of turbine generator sets. Specifically, this involves new construction and service documentation for gas turbines, condensers, generators, and steam turbines for power generation. New additions include hydrogen production plants, power transmission plants (high-voltage converters), and tool and fixture documentation for power plant construction. Not all areas are at the same level in terms of the implementation of iiRDS; some are still being converted or developed.

How do you use iiRDS in technical writing?

Michael Straeter: So far, we have mainly used the standard for classification, structuring, and building a cross-system ontology (we have two different CCMSs in use), but also in the area of automatic metadata recognition and assignment. We do not yet use it as an exchange format. But that is an important goal.

Have you brought in external support?

Michael Straeter: We had expertise right from the start. It wouldn't have worked without it. After the initial internal deliberations, we started a PoC [Proof of Concept]. We then investigated how we could generate iiRDS packages from heterogeneous sources, largely without converting the CCMS. Now that this also seems achievable, we are focusing on automated interfaces and process automation. CCMS manufacturers are now also supporting us, and more could be added in the areas of CDP [Content Delivery Portal] and customer clouds (which we would like to operate with iiRDS). The topics of language analysis and terminology also play a role. We have been working closely with partner companies in this area for some time.

Which other departments are involved in the implementation of iiRDS?

Michael Straeter: We plan and pursue the implementation within the Technical Editing department in small agile project teams. In the direct environment of our department, we had to deal with our mostly internal customers at an early stage. After all, the standard also has an impact on our information products. Once we had made our main goals clear – standardization, a leaner and more future-proof information model, and additional automation options – we were readily supported. It certainly helped that a whole series of processes were and still are undergoing change as a result of the spin-off from Siemens AG to Siemens Energy.

Beyond our department, we are now networked with teams that deal with issues of enterprise data, data quality, data governance, and ontology at a higher organizational level. We are trying to get involved there and make the topic of “usage information” a strong one – after all, this is part of every product and every service. iiRDS is met with great interest here. In the future, we will try to incorporate our expertise in this field into higher-level data and information models. This promises to be all the more successful, the more prominent iiRDS becomes as a standard, and the better our information products and processes reflect this.

Tobias Köffer: In the short term, we are initially implementing iiRDS in the technical writing environment. In the medium and long term, we also want to use the ontologies mentioned, especially in those areas that cannot be specified by iiRDS. These include, in particular, the structure of our products and services as well as the detailed stages of the life cycle that a power plant goes through.

Do you also involve your suppliers?

Michael Straeter: Not now. At the moment, it is us and some of our network partners who are promoting the standard within the company. Given the vast number of internal and external information suppliers – we are on the move with our products worldwide – we cannot assume that iiRDS will establish itself as a standard across the board in our product area. We are also dealing with a traditionally conservative, long-term, and highly specialized sector in energy generation. This also applies to technical documentation. Thus, we are working more on making the supplied information “iiRDS-ready” and integrating it into the standard.

Tobias Köffer: The integration of information suppliers is traditionally somewhat difficult. This applies to both internal and external suppliers. We can't assume that suppliers will take on the issue of their own accord. We therefore tend to try to lower the entry barrier and make it as easy as possible for us to process the information, for example, through automated metadata recognition and assignment.

How have processes in technical writing changed with the introduction of iiRDS?

Michael Straeter: So far, hardly at all. Our current assessment is that the editorial process will not necessarily have to change after the introduction of the adapted classification structure, at least not as a result of iiRDS. As soon as the creation of iiRDS packages – whether inside or outside the CCMS – is largely automated, employees will basically only have to quality assure a different format.

Of course, we had to bring all employees on board, especially in the area of taxonomy and classification, which is change management. Some information products are already iiRDS-compliant, others have to be converted retrospectively. This is an expensive and lengthy process that is repeatedly slowed down by delivery deadlines and the resulting workarounds. But we hope that in one to two years we will have reached the point where old taxonomy structures have reached the end of their life cycle.

Tobias Köffer: The fact that the editorial process remains largely unchanged is definitely a big plus. In practice, harmonization often goes hand-in-hand with a certain amount of disruption to day-to-day business or established processes. In view of our order situation, it is not advisable to intervene too deeply in the process.

Michael Straeter: But something else has changed as a result of iiRDS, namely, the desire to standardize and minimize other areas in the same way and make them more comparable. From our point of view, DIN EN IEC/IEEE 82079-1 provides a kind of framework for subjecting information products (“information for use”), creation and provision processes, necessary qualifications, and required resources to a fundamental revision. This is because, as the standard clearly describes, ultimately these areas cannot be separated from each other but, on the contrary, should should build on each other in a meaningful way.

As already mentioned, some of the content structures have changed. Since the introduction of iiRDS, we have adopted a much more generic approach and no longer try to map project and customer-specific tables of contents at all costs, for example.

Figure 2: Model of a gas and steam power plant; the technical editorial department now also produces documentation for the large components supplied with the aid of iiRDS.

Source: © Siemens Energy

What future benefits do you expect from iiRDS?

Michael Straeter: We are pleased that iiRDS practice has picked up speed in recent years. The dissemination and practical experience support the efforts to spread and standardize iiRDS internationally. We have also seen that iiRDS can now be integrated into other standards, such as Industry 4.0/AAS, ECLASS, or VDI 2770. In this way, information and products can be brought closer together. Things that are comparable to each other, such as information for use, can now be presented in an information space and applied to a wide variety of product areas. This is where we hope to see real progress in the digital exchange of information. Above all, however, we hope that the iiRDS standard will make information provision much more dynamic and target group-oriented. On the content management side, we have been able to provide more than just PDFs for some time now.

Tobias Köffer: If we look at the big issues of recent years, such as ChatGPT, these are also making waves in the traditional power plant construction environment. This has led to an increased interest in metadata and the various ways of providing information, especially outside of technical editing. iiRDS seemed to be the natural choice to meet this demand and provide solutions across the entire spectrum of knowledge graphs, Artificial Intelligence (AI), Large Language Models (LLMs), and more.

Where do you see potential for improvement in iiRDS?

Michael Straeter: Frequent criticism concerns deficits in the “request”, and we can agree with that. What could a query language based on a standard look like that focuses primarily on the user's perspective? We believe that this is less a technical question and more a question of agreement. Target groups, individual product variants, and their product life cycles require a complex information structure. On the one hand, this requires quick and comprehensive orientation, but also the shortest possible path from question to answer. That remains a challenge.

Tobias Köffer: By its very nature, the standard unfolds at the meta-level, and this is where most of the discussions and arguments in favor of this standard arise. This debate is reserved for a relatively small specialist audience and requires a considerable amount of familiarization with a complex topic. There is currently a lack of suitable tools to better emphasize the advantages, especially at the semantic level, outside the specialist audience. This applies not only to the request part but also to the entire life cycle of the information. The easier it becomes to create and interact with iiRDS content, the greater the overall interest will be.

About Siemens Energy

As a global energy technology company, Siemens Energy supports its customers along the entire energy value chain: low-emission or emission-free generation, transportation and storage, reduction of greenhouse gas emissions, and energy consumption in industrial processes.

About the technical writing team

More than 40 employees produce technical documentation in the "Field Data Manuals" department. They are supported by around ten partner companies. Every year, 200 technical documents are produced for global projects. The Technical Writing department works on over 40 information products, which are used in around 40 product series and for services.