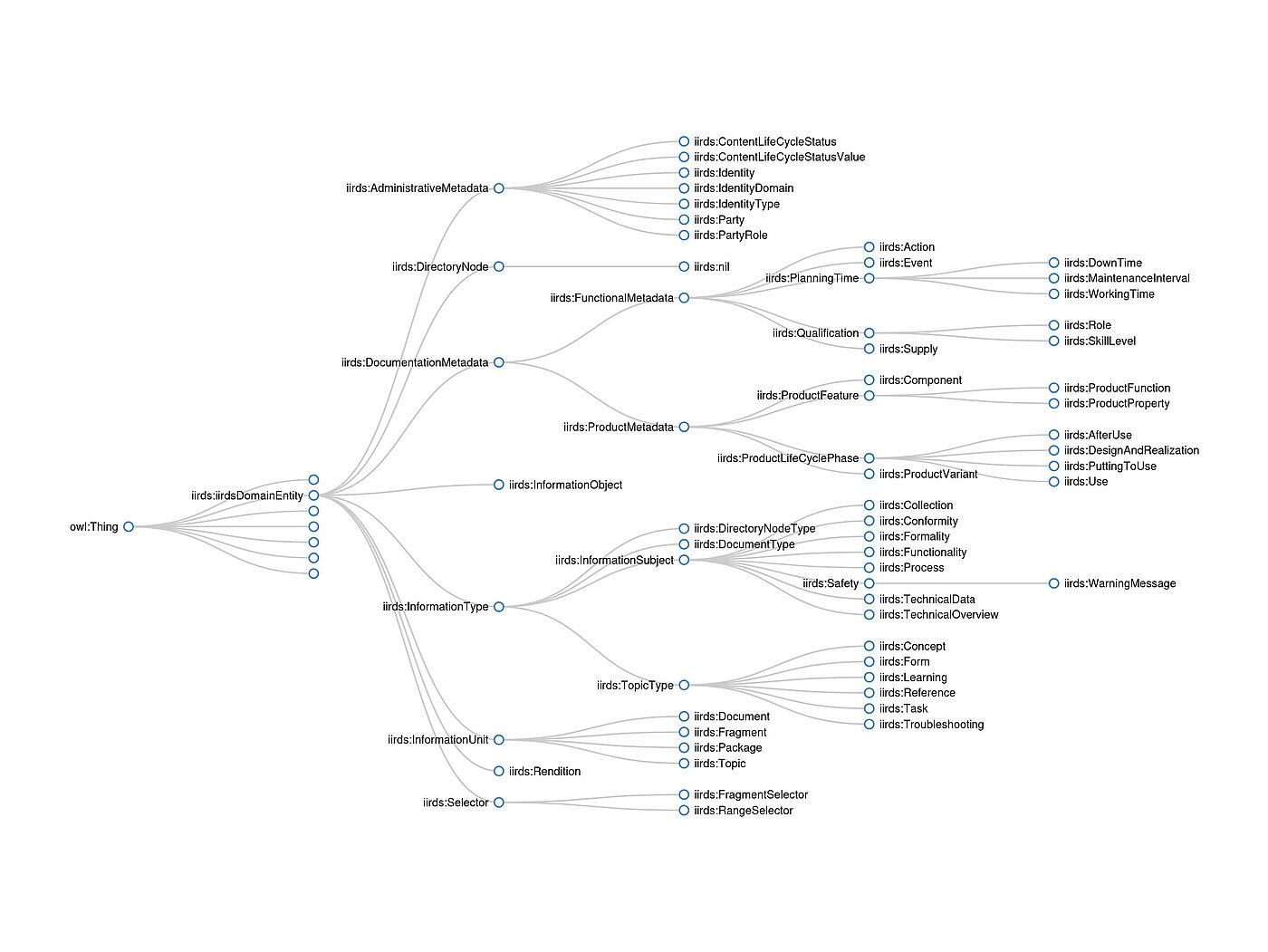

The intelligent information Request and Delivery Standard (iiRDS), which emerged from a tekom working group, has been in development since 2016. It aims to standardize the delivery and exchange of technical information. To do so, the standard provides predefined metadata classes, their relations with each other, and a package format for data exchange.

So, is iiRDS only for large technical editorial teams? Can only large corporations afford the resources necessary for its implementation? Berlin-based company Knick provides insights into how the standard helped the medium-sized company meet the demand for interconnected information.

How we came across iiRDS

We have been following the development of iiRDS since its inception. I then took a deeper look at the standard when we first introduced our component content management system (CCMS). The goal was to find a suitable metadata model for structuring our product information. We originally chose the PI Classification – a classification scheme for modular content in technical communication – as this sufficiently covered our requirements. At that time, there was no suitable use case for iiRDS in our company.

Metadata, particularly iiRDS, gain signifance

About two years ago, the topic of interconnected information became much more important, as our customers demanded product information in compliance with the VDI 2770 industry standard. In addition, in the context of Industry 4.0, we started developing a system that generates asset administration shells for the digital twin according to the specifications of the Industrial Digital Twin Association (IDTA). At the same time, we faced new challenges due to increasing product and variant diversity, Knick's international growth, and the difficulty of finding existing information.

In addition, the editorial team wanted to make our product information available digitally via a content delivery portal (CDP). This was the result of rising printing costs and the many manual steps involved in the print publication process.

So, the need for structured, enriched information was omnipresent, and it quickly became clear that our previous approach was no longer sufficient. With its standardized data exchange and well-designed metadata classes, iiRDS offered an ideal alternative.

Introducing iiRDS to the editorial team

After attending a basic training course at tekom, I became aware of a pilot project sponsored by the iiRDS Consortium – the perfect opportunity to tackle the issue and introduce iiRDS to the company.

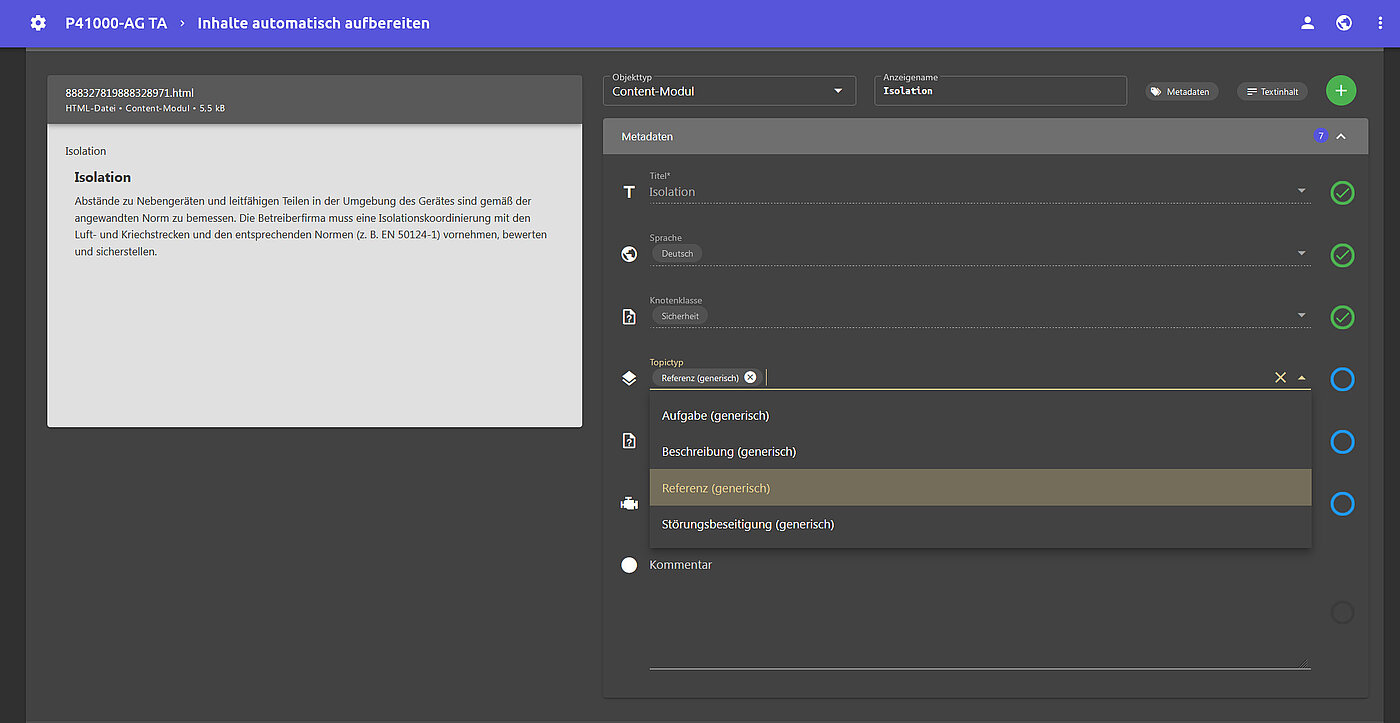

In 2024, we successfully completed the pilot project in collaboration with the company plusmeta. Internal activities for metadata modeling are currently underway. At the moment, I am working on the final implementation in the test system of our CCMS and adding iiRDS metadata to the first content.

This will be followed by a kick-off with the entire editorial team. A project like this can only succeed if everyone involved is convinced and on board. After that, we want to analyze our existing data and transfer it to a more topic-oriented structure. If everything goes well, the iiRDS model will be transferred to our production environment within one year. Since manually tagging our extensive existing data is not practical, we plan to use a tool to automate this process.

So, our journey with iiRDS has only just begun. But the foundations are in place, and the first iiRDS packages with real content have already been successfully generated as part of the pilot project.

External support

As already mentioned, we brought in the company plusmeta for our iiRDS pilot project because of their expertise in this area. This collaboration was extremely valuable – the insights gained were directly incorporated into our digitization strategy.

The automated tagging of metadata using various methods clearly showed how much this process can be accelerated.

The plusmeta tool used dynamic extractors based on pattern recognition. In addition, metadata already available in the CCMS was used by means of rule-based systems. The relationships between the different data models were mapped in a knowledge graph, which in turn served as the basis for suitable mappings.

We carried out the actual modeling and implementation of the metadata in the CCMS internally. However, before we start tagging the inventory data, we would like to obtain an independent evaluation. In general, I think it makes sense to bring in external expertise – after all, a project like this is not an everyday matter.

Challenges for small editorial teams

The biggest challenge was implementing the project alongside our day-to-day editorial work. In our small team, there is no dedicated position for such topics. You need to take the initiative and set aside specific periods of time to work on it.

In addition, it was not easy at first to position this abstract topic within the company and demonstrate its benefits. However, small companies have the advantage of direct communication and short decision-making processes. Nevertheless, such considerations must fit sensibly into the company's digitalization strategy. Ultimately, it is important to realistically assess whether initiatives such as iiRDS are a good fit for the company and can actually be implemented.

The costs have remained manageable so far – thanks in part to a € 5,000 grant as part of the pilot project. For our small editorial team in particular, this was a decisive incentive to get started right away without any major initial hurdles.

Tips for editorial teams that want to work with iiRDS

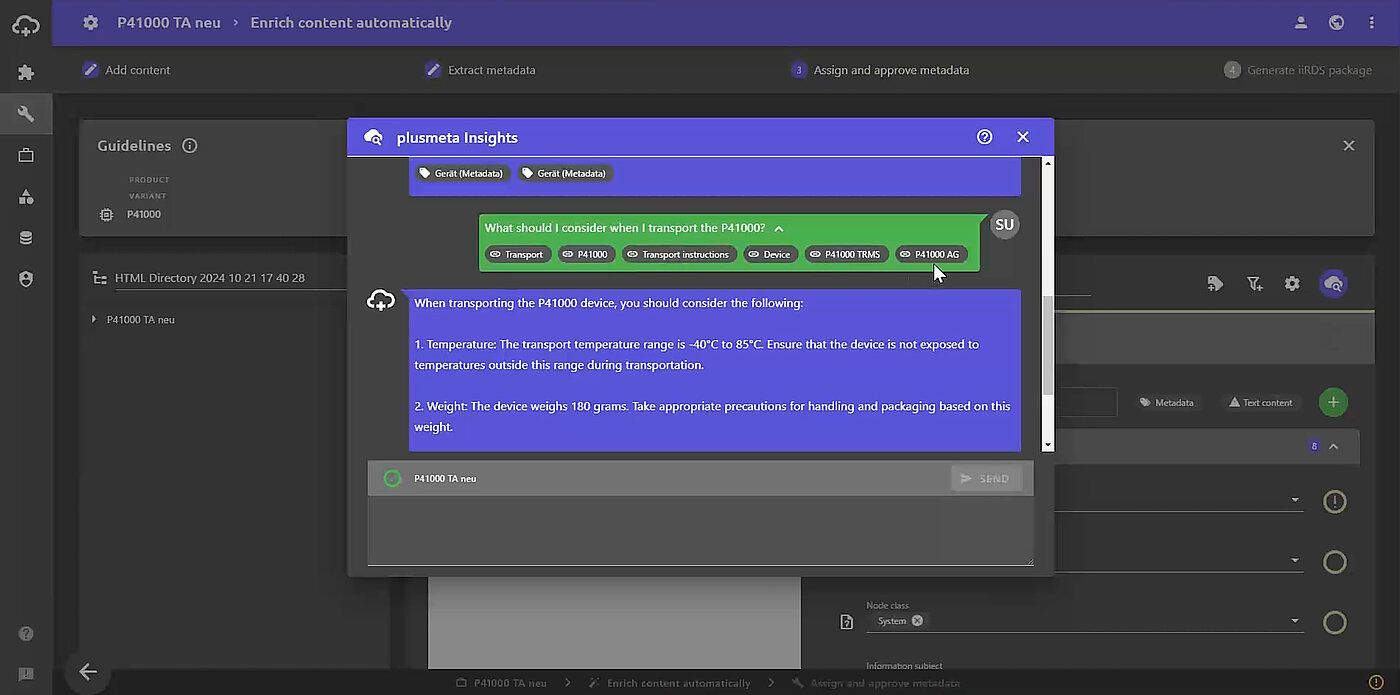

In my experience, it is crucial to show real application examples – preferably with your own product information. In the pilot project, plusmeta put together convincing use cases that revealed iiRDS’ potential. One example was an optimized chatbot whose responses were enriched with iiRDS metadata and a knowledge graph with concrete, domain-specific knowledge, see Figure 3.

My recommendation: Develop your own use cases, coordinate them internally, and proceed in small steps. It is not necessary to exploit all possibilities immediately. It might be sufficient to use only a few iiRDS classes at first and develop the model further later. The implementation of iiRDS is an iterative process that continuously adapts to changing requirements.

In addition, it is worth questioning what exactly is to be achieved by introducing iiRDS. Therefore, we defined our goals in a digitization strategy. This clarified the issues that needed to be solved.

Misunderstandings about iiRDS

There is often confusion about the fact that iiRDS provides both a vocabulary for metadata and a package format for data exchange. For getting started, the vocabulary is the most interesting part – it is the logical first step before the exchange.

iiRDS provides a framework for the formal representation of knowledge and the relationships between concepts – specialized and limited to technical documentation. The standard is deliberately kept lightweight and optimized for metadata interoperability, not for complex logical conclusions.

However, this also means that not every information requirement is represented in iiRDS. Thanks to its modular architecture, however, extensions and external concepts can be easily integrated. In addition to the base model (Figure 4), two domain-specific extensions already exist for mechanical engineering and software documentation. Accordingly, extensions suitable for your own domain can be developed and integrated according to the same principle. The degree of adaptation required varies depending on the needs and application context – iiRDS provides the technical basis for this.

Future benefits

We consider it essential to integrate modular information within the concept of the digital twin. The IDTA's “Intelligent Information for Use” submodel, published in March 2025, now offers a standardized template for integrating iiRDS-enriched product documentation into administration shells. We will closely monitor this development and evaluate whether there are specific use cases for us.

Another exciting development in the field of automated information exchange is the application programming interface (API) developed by the iiRDS Consortium. The so-called iiRDS Request API defines a RESTful interface for retrieving specific information from systems that use iiRDS metadata.

We have already experimented with the integration of ECLASS in the pilot project, and we would like to pursue this approach further. In addition, we are currently addressing issues relating to digital training offerings and domain-specific content generation using retrieval-augmented generation (RAG) in conjunction with Large Language Models (LLMs).

Promising developments have since emerged, and we are identifying more and more potential application opportunities. The examples illustrate the potential of iiRDS – and I am sure that more will follow.

Tool support for iiRDS

In recent years, the iiRDS Consortium has developed helpful tools. These include generators and validators for iiRDS packages, a DITA plug-in, and the aforementioned Request API.

Many CCMSs offer metadata modeling capabilities, but native iiRDS support varies. Predefined configurations or simple import options are not always available. Direct generation of iiRDS packages from the CCMS is also not yet possible with every system. With our CCMS SCHEMA ST4, this could be implemented via a customized production layout with the Online Media Designer (OMD) or by integrating the plusmeta tool.

So, there are approaches from software manufacturers, but simple turnkey solutions are still rare. Lower entry barriers would make implementation much easier, especially for small teams.

Room for improvement in iiRDS

The standard covers the requirements of technical documentation very well. If something is missing in a particular case, iiRDS can be flexibly expanded. This makes the standard a good starting point, especially for small companies – much easier and cheaper than developing their own model from scratch. There are now also practical solutions for data exchange.

In my opinion, the biggest challenge is communicating the benefits and potential – both within the technical editorial department and to management. In this regard, it could be helpful to provide supporting arguments on the benefits and guidelines for developing key performance indicators that can be used to measure improvements.

It would also be desirable to have a test instance of a CDP that can process iiRDS packages natively. This would allow teams to demonstrate advantages directly and in a practical manner – either with their own packages or with sample content. To get decision-makers on board and allocate the necessary resources, they need to be able to see the potential of iiRDS in practical use.

The international standardization of iiRDS has already been initiated and will help to establish the standard outside of Europe as well. However, the real strategic benefits will only unfold with practical implementation – as the basis for automated processes, interconnected information, and future-proof information systems.

A highly specialized and multi-skilled team of five employees creates the technical documentation for Knick products. This information is included with the products in printed form and is also made available electronically as PDF files, including in other languages. In addition, the department is responsible for translation management, terminology work, and the creation of technical illustrations throughout the company. Digitalization is a high priority: The team is involved in various projects in which information is integrated into digital processes, such as the creation of asset administration shells.

Knick is a global industrial company that offers solutions for measuring current, voltage, temperature, and speed, as well as for measuring pH, ORP, conductivity, and oxygen in process analytics. The company's roots and headquarters have been in Germany since 1945 and are closely associated with the “Made in Germany” quality standard.

plusmeta is an innovative company that combines scientific and pragmatic thinking with state-of-the-art technology. Founded in 2019, plusmeta specializes in intelligent information and technical documentation. Since 2023, plusmeta has been part of the Quanos Group, but remains an independent entity and continues to support a wide range of software systems.